Roll to Roll

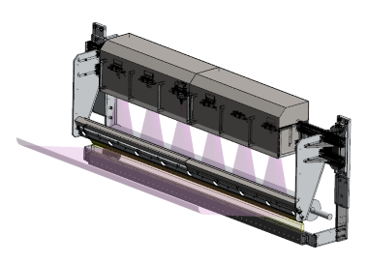

UniScan-S Inline Surface Inspection Machine

The equipment inspects thickness of coating layers between transparent materials used in Roll-to-Roll processes.

High performance camera achieves rapid and precise detection of defects, e.g. impurities, pinholes, and scratches on surface.

Inspection algorithm

Real-time inspection of foreign substances, scratches, air bubbles, pinholes, stains, etc. that may occur on the surface of various roll-type materials such as functional films, optical films, and laminating films

Key Features

-UniEye's system incorporating high-resolution cameras, optimized lighting, image processing algorithms, and deep learning classifiers is designed to be R2R process-specific

-Even fast-moving films detect defects and automatically categorize them

-Various optical system configurations to meet film production process inspection requirements

-Application of visible light, UV, IR, etc. / High-speed Line Scan camera and multi-PC adoption

-Even fast-moving films detect defects and automatically categorize them

-Various optical system configurations to meet film production process inspection requirements

-Application of visible light, UV, IR, etc. / High-speed Line Scan camera and multi-PC adoption

![]()

![]()

![]()

Key Features

- Intuitive and easy-to-use user UI

- Provides automatic teaching for quick teaching settings

- Teaching and inspection condition setting according to model, inspection and data storage & report, classification and alarm by defect type, statistical function by defect type, etc

- Report: Defect maps, defect information, classification and statistics, trend charts, graphs by distance, etc

- Provides automatic teaching for quick teaching settings

- Teaching and inspection condition setting according to model, inspection and data storage & report, classification and alarm by defect type, statistical function by defect type, etc

- Report: Defect maps, defect information, classification and statistics, trend charts, graphs by distance, etc

Connecting with a variety of systems

-Marking devices such as labelers, pen markers, lasers, etc., and PLC interworking

-Remote control and monitoring via external PC and I/O viewer

-AI-based defect classifier applicable (Defect Classification & Cluster)

-Application of transfer mechanism to suppress film vibration in the process

-Management of production history through linkage of higher systems such as MES

-Remote control and monitoring via external PC and I/O viewer

-AI-based defect classifier applicable (Defect Classification & Cluster)

-Application of transfer mechanism to suppress film vibration in the process

-Management of production history through linkage of higher systems such as MES

Product Specifications

Category | Specification | Note |

Camera | 2K/4K/6K/8K/16K Line Scan | |

Applications | Max 16 EA Camera | |

Resolution | 40/20/10 ㎛ / pixel | |

Light | Top & Bottom LED Bar Light | |

PLC | Ethernet or DIO | |

Items | Uncoating/Pinhole/Contaminant/Etc | |

Speed | Up to 200m/min | Standard base Depends on Resolution |

Option | External Encoder / Labeler |